MAX16834 是Maxim公司的 电流模式高亮LED(HBLED)驱动器,可用于升压,升压-降压,SEPIC和高边降压拓扑. 工作电压4.75V 到 28V,3000:1 PWM调光/模拟调光,可编频率从100kHz到1MHz,主要用在单串LED LCD背光,汽车前后照明,投映系统RGB LED光源,点和环境照明以及DC/DC升压/升-降压转换器.本文介绍了MAX16834主要特性,方框图,多种应用电路以及112W升压LED驱动器参考设计,电路图和材料清单(BOM).

The MAX16834 is a current-mode high-brightness LED (HB LED) driver for boost, boost-buck, SEPIC, and highside buck topologies. In addition to driving an n-channel power MOSFET switch controlled by the switching controller, it also drives an n-channel PWM dimming switch to achieve LED PWM dimming. The MAX16834 integrates all the building blocks necessary to implement a fixed-frequency HB LED driver with wide-range dimming control.

The MAX16834 features constant-frequency peak current- mode control with programmable slope compensation to control the duty cycle of the PWM controller.

A dimming driver designed to drive an external n-channel MOSFET in series with the LED string provides wide-range dimming control up to 20kHz. In addition to PWM dimming, the MAX16834 provides analog dimming using a DC input at REFI. The programmable switching frequency (100kHz to 1MHz) allows design optimization for efficiency and board space reduction.

A single resistor from RT/SYNC to ground sets the switching frequency from 100kHz to 1MHz while an external clock signal at RT/SYNC disables the internal oscillator and allows the MAX16834 to synchronize to an external clock. The MAX16834’s integrated highside current-sense amplifier eliminates the need for a separate high-side LED current-sense amplifier in boost-buck applications.

The MAX16834 operates over a wide supply range of 4.75V to 28V and includes a 3A sink/source gate driver for driving a power MOSFET in high-power LED driver applications. It can also operate at input voltages greater than 28V in boost configuration with an external voltage clamp. The MAX16834 is also suitable for DCDC converter applications such as boost or boostbuck.

Additional features include external enable/ disable input, an on-chip oscillator, fault indicator output (FLT) for LED open/short or overtemperature conditions, and an overvoltage protection sense input (OVP+) for true overvoltage protection.

The MAX16834 is available in a thermally enhanced 4mm x 4mm, 20-pin TQFN-EP package and in a thermally enhanced 20-pin TSSOP-EP package and is specified over the automotive -40℃ to +125℃ temperature range.

MAX16834主要特性:

_ Wide Input Operating Voltage Range (4.75V to 28V)

_ Works for Input Voltage > 28V with External Voltage Clamp on VIN for Boost Converter

_ 3000:1 PWM Dimming/Analog Dimming

_ Integrated PWM Dimming MOSFET Driver

_ Integrated High-Side Current-Sense Amplifier for LED Current Sense in Boost-Buck Converter

_ 100kHz to 1MHz Programmable High-Frequency Operation

_ External Clock Synchronization Input

_ Programmable UVLO

_ Internal 7V Low-Dropout Regulator

_ Fault Output (FLT) for Overvoltage, Overcurrent, and Thermal Warning Faults

_ Programmable True Differential Overvoltage Protection

_ 20-Pin TQFN-EP and TSSOP-EP Packages

MAX16834应用:

Single-String LED LCD Backlighting

Automotive Rear and Front Lighting

Projection System RGB LED Light Sources

Architectural and Decorative Lighting (MR16, M111)

Spot and Ambient Lights

DC-DC Boost/Boost-Buck Converters

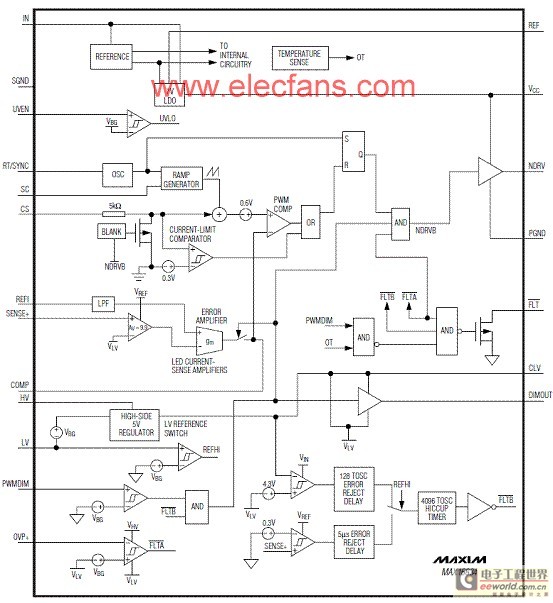

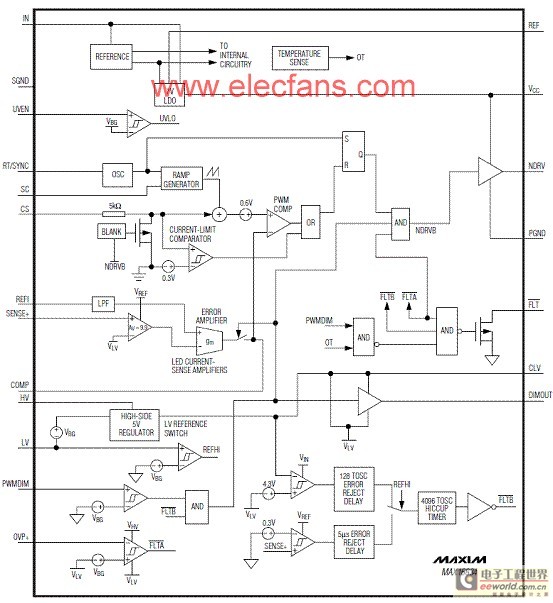

图1.MAX16834内部方框图

图2.MAX16834升压LED驱动器

图3.MAX16834升压-降压LED驱动器(VLED+ < 28V)

图4.MAX16834带汽车负载突变保护的升压LED驱动器

图5.MAX16834高边降压LED驱动器

图6.MAX16834升压DC/DC转换器

图7.MAX16834升压-降压DC/DC转换器

全陶瓷电容的112W升压长串LED驱动器参考设计

112W boost driver for long strings of LEDs using all ceramic capacitors

This is a reference design for a 112.5W boost LED driver that uses the MAX16834 for long strings of LEDs. These long LED strings are commonly found in streetlights and parking garage lights.

Input voltage: 24VDC ±5% (at 1.49A)

VLED configuration: Two parallel strings. Each string consists of 19 WLEDs and a 5Ω resistor for current balancing. Current is 750mA per sting for a total of 1.5A into 75V.

Dimming: 50μs (min) on-pulse for up to a 200:1 dimming ratio with a 100Hz dimming frequency

图8.112W升压长串LED驱动器参考设计外形图

图9.112W升压长串LED驱动器参考设计电路图

112W升压长串LED驱动器参考设计材料清单(BOM):

关键字:MAX16834 LED 驱动器

编辑:神话 引用地址:基于MAX16834设计的112W升压LED驱动器技术

The MAX16834 is a current-mode high-brightness LED (HB LED) driver for boost, boost-buck, SEPIC, and highside buck topologies. In addition to driving an n-channel power MOSFET switch controlled by the switching controller, it also drives an n-channel PWM dimming switch to achieve LED PWM dimming. The MAX16834 integrates all the building blocks necessary to implement a fixed-frequency HB LED driver with wide-range dimming control.

The MAX16834 features constant-frequency peak current- mode control with programmable slope compensation to control the duty cycle of the PWM controller.

A dimming driver designed to drive an external n-channel MOSFET in series with the LED string provides wide-range dimming control up to 20kHz. In addition to PWM dimming, the MAX16834 provides analog dimming using a DC input at REFI. The programmable switching frequency (100kHz to 1MHz) allows design optimization for efficiency and board space reduction.

A single resistor from RT/SYNC to ground sets the switching frequency from 100kHz to 1MHz while an external clock signal at RT/SYNC disables the internal oscillator and allows the MAX16834 to synchronize to an external clock. The MAX16834’s integrated highside current-sense amplifier eliminates the need for a separate high-side LED current-sense amplifier in boost-buck applications.

The MAX16834 operates over a wide supply range of 4.75V to 28V and includes a 3A sink/source gate driver for driving a power MOSFET in high-power LED driver applications. It can also operate at input voltages greater than 28V in boost configuration with an external voltage clamp. The MAX16834 is also suitable for DCDC converter applications such as boost or boostbuck.

Additional features include external enable/ disable input, an on-chip oscillator, fault indicator output (FLT) for LED open/short or overtemperature conditions, and an overvoltage protection sense input (OVP+) for true overvoltage protection.

The MAX16834 is available in a thermally enhanced 4mm x 4mm, 20-pin TQFN-EP package and in a thermally enhanced 20-pin TSSOP-EP package and is specified over the automotive -40℃ to +125℃ temperature range.

MAX16834主要特性:

_ Wide Input Operating Voltage Range (4.75V to 28V)

_ Works for Input Voltage > 28V with External Voltage Clamp on VIN for Boost Converter

_ 3000:1 PWM Dimming/Analog Dimming

_ Integrated PWM Dimming MOSFET Driver

_ Integrated High-Side Current-Sense Amplifier for LED Current Sense in Boost-Buck Converter

_ 100kHz to 1MHz Programmable High-Frequency Operation

_ External Clock Synchronization Input

_ Programmable UVLO

_ Internal 7V Low-Dropout Regulator

_ Fault Output (FLT) for Overvoltage, Overcurrent, and Thermal Warning Faults

_ Programmable True Differential Overvoltage Protection

_ 20-Pin TQFN-EP and TSSOP-EP Packages

MAX16834应用:

Single-String LED LCD Backlighting

Automotive Rear and Front Lighting

Projection System RGB LED Light Sources

Architectural and Decorative Lighting (MR16, M111)

Spot and Ambient Lights

DC-DC Boost/Boost-Buck Converters

图1.MAX16834内部方框图

图2.MAX16834升压LED驱动器

图3.MAX16834升压-降压LED驱动器(VLED+ < 28V)

图4.MAX16834带汽车负载突变保护的升压LED驱动器

图5.MAX16834高边降压LED驱动器

图6.MAX16834升压DC/DC转换器

图7.MAX16834升压-降压DC/DC转换器

全陶瓷电容的112W升压长串LED驱动器参考设计

112W boost driver for long strings of LEDs using all ceramic capacitors

This is a reference design for a 112.5W boost LED driver that uses the MAX16834 for long strings of LEDs. These long LED strings are commonly found in streetlights and parking garage lights.

Input voltage: 24VDC ±5% (at 1.49A)

VLED configuration: Two parallel strings. Each string consists of 19 WLEDs and a 5Ω resistor for current balancing. Current is 750mA per sting for a total of 1.5A into 75V.

Dimming: 50μs (min) on-pulse for up to a 200:1 dimming ratio with a 100Hz dimming frequency

图8.112W升压长串LED驱动器参考设计外形图

图9.112W升压长串LED驱动器参考设计电路图

112W升压长串LED驱动器参考设计材料清单(BOM):

上一篇:基于dsPIC33F和PIC24H设计的Microstick

下一篇:基于LT3575设计的隔离反激型电源转换技术

推荐阅读最新更新时间:2023-10-13 10:55

LED电源驱动电路热阻详细计算方法

高温或内部功耗产生的过多热量可能改变电子元件 的特性并导致其关机、在指定工作范围外工作,甚或出现故障。电源管理 器件(及其相关电路)经常会遇到这些问题,因为输入与负载之间的任何功耗都会导致器件发热,所以必须将热量从这些器件中驱散出来,使其进入PCB 、附近的元器件或周围的空气。即使在传统高效的开关电源 中,当设计PCB和选择外部元器件时,也都必须考虑散热问题。

设计电源管理电路时,在考察散热问题之前对热传递进行基本了解是很有帮助的。首先,热量是一种能量,会由于两个系统之间存在温差而进行传输。热传递通过三种方式进行:传导、对流和辐射。当高温器件接触到低温器件时,会发生传导。高振幅的高温原子与低温材料的原子碰撞,从而增加低

[电源管理]

央视315曝光的LED灯频闪,你所不知道的那些事!

央视“3·15”晚会曝光了各种造假行为,其中有一个环节还教大家识别LED灯是否存在严重的频闪问题。正是这个环节引起了小编的注意,频闪?这是为什么? 一起深扒这个技术问题之前,先来回放一下315晚会的这个检测。 两位实验员,两盏LED灯,一台专用的频闪测试仪。 如果波形比较平缓,说明频闪几乎为零;波形幅度非常大,则说明频闪很严重。 LED灯为何会出现频闪? 现在我们就来了解一下,拥有发光效率高、寿命长、可靠性高等诸多优势的LED照明产品,为何会出现频闪?频闪又是个什么概念? LED灯由于响应速度快,且也不具备传统灯具的热惯性和余辉效应,因此深受电流波动的影响。电流的波动直接影响光通量的输出,而

[电源管理]

有关LED的一些基础知识点

一、 LED 不是 冷光源

很多人都知道LED是冷光源,从字面上理解应该是没有温度的发光体,事实上并不是这样,冷光源不代表没有温度,只是相对目前大多数光源来讲是冷光源。LED正常工作的时候一样会有自身的热量,其热量大小与LED自身的 功率 成正比,也就是说单颗LED功率越大,工作的时候发出的热量也越多。

二、 光学 设计的重要性

LED是点光源,不同于目前市场上的节能灯或白炽灯。点光源 顾名思义也就是一个点发出的光亮,而这个点发出光还同时具有另一个重要特征,那就是只有一方向上有光(所有传统的背面反光罩对于LED本身来说是没有任何意义的)。如果我们想要用这种特殊的光来做照明使用

[电源管理]

用CPLD设计LED显示屏控制电路

引言

近年来,随着计算机技术和集成电路技术的飞速发展,得到广泛应用的大屏幕显示系统当属视频LED显示系统。在LED显示技术中,由于红色、绿色发光二极管的亮度、光效色差等性能也得到了很大的提高,加之计算机多媒体制作软件的发展,现在伪彩视频LED显示系统的制造成本大大降低,应用领域不断增加。这种伪彩色视频LED显示系统采用了计算机多媒体技术,全同步动态显示视频图像,图像清晰,亮度高,无拼缝,每种颜色的视频灰度等级已经由早期的16级灰度上升现在的256灰度,随着大规模集成电路和专用元器件的发展,256级灰度的全彩色视频LED显示系统随时都可能实现。

LED电子显示技术发展迅速,已成为当今平板显示领域的主导之一。

[电源管理]

s3c2440学习之路-002 C语言点亮led

硬件平台:jz2440 软件平台:Ubuntu16.04 arm-linux-gcc-3.4.5 源码位置: https://github.com/lian494362816/C/tree/master/2440/003_led_c 1 主要流程 承接上一篇博客 https://blog.csdn.net/lian494362816/article/details/84309342, 原理分析就略过,流程也很简单: 1)设置栈 2)跳到C语言 3)将GPF4配置成输出模式 4)将GPF4输出低电平,即可点亮LED1 2 源码 start.s .global _start _start: ldr sp, =409

[单片机]

单片机LED点阵的介绍

点阵 LED 显示屏作为一种现代电子媒体,具有灵活的显示面积(可任意分割和拼装)、高亮度、长寿命、数字化、实时性等特点,应用非常广泛。 前边学了 LED 小灯和 LED 数码管后,学 LED 点阵就要轻松得多了。一个数码管是8个 LED 组成,同理,一个88的点阵就是由64个 LED 小灯组成。图7-1就是一个点阵 LED 最小单元,即一个88的点阵 LED,图7-2是它的内部结构原理图。 图7-1 8*8 LED 点阵外观 图7-2 8*8点阵结构原理图 从图7-2上可以看出,其实点阵 LED 点亮原理还是很简单的。在图中大方框外侧的就是点阵 LED 的引脚号,左侧的8个引脚是接的内部 LED 的阳极,上侧的8个引脚接的

[单片机]

LED照明市场引爆对LED驱动器的巨大需求

早在2003年,Lumileds Lighting公司的Roland Haitz就提出,LED大约每经过18到24个月可提升一倍的亮度,这就是著名的Haitz定律(图1),也被称为LED行业的摩尔定律。根据这个定律,具有突破性质的亮度达100lm/W的LED约在2008~2010年间出现。实际上,2006年6月日本日亚化学公司就推出100lm/W白光 LED工程样品,2007年6月Cree宣布推出在350mA下最小光通量为100lm的高亮度LED。

图1 LED大约每经过18到24个月提升一倍的亮度

研究显示,仅仅在美国,如果55%的白炽灯和55%的日光灯被LED取代,每年将节省350亿美元电费,减少

[电源管理]

电池供电产品的LED控制问题

摘要:白光LED具有使用简单、成本低的特点,其用量在最近几年呈现出稳步上升的趋势,在例携式产品中被广泛用作闪光灯、显示器背光等。本文介绍几种白光LED的驱动方案。

关键词:白光LED 便携式产品 DC-DC转换器

1 概述

LED为电流驱动器件,光输出强度由流过二极管的电流决定。图1是由电压源和限流电阻构成的一种简单偏置电路,流过LED的电流由下式确定:IDIODE=(VCC-VF)/ 这种方式成本较低,但不同的二极管VF(正向电压)的参数一致。图2、图3表示25℃时LED的正向电压(典型值)与导通电流关系曲线。从电流指标可以看出:对于GaAsP二极管,VF可以上升到2.7V(+40%);对于InGaN二极管,VF可以上程

[电源管理]

小广播

热门活动

换一批

更多

最新电源管理文章

更多精选电路图

更多热门文章

更多每日新闻

- PC产业驶入创新超车道,英特尔蓉城撬动AI新引擎

- 与产业聚力共赢,英特尔举行新质生产力技术生态大会

- “新”享5G-A万兆网络前沿体验 高通携手产业伙伴亮相第二届链博会

- 英飞凌推出符合ASIL-D标准的新型汽车制动系统和电动助力转向系统三相栅极驱动器 IC

- 南芯科技推出80V升降压转换器,持续深耕工业储能市场

- 法雷奥与罗姆联合开发新一代功率电子领域

- 贸泽电子开售能为电动汽车牵引逆变器提供可扩展性能的 英飞凌HybridPACK Drive G2模块

- 德州仪器新型 MCU 可实现边缘 AI 和先进的实时控制, 提高系统效率、安全性和可持续性

- 瑞萨推出高性能四核应用处理器, 增强工业以太网与多轴电机控制解决方案阵容

- 研华全新模块化电脑SOM-6833助力5G路测设备升级

更多往期活动

厂商技术中心

blinker_app_control_the_led_on_the_feather_border.

blinker_app_control_the_led_on_the_feather_border. 【用户手册】带+STM32MP157+MPU+的评估板

【用户手册】带+STM32MP157+MPU+的评估板 硬件架构艺术:数字电路的设计方法与技术

硬件架构艺术:数字电路的设计方法与技术

京公网安备 11010802033920号

京公网安备 11010802033920号